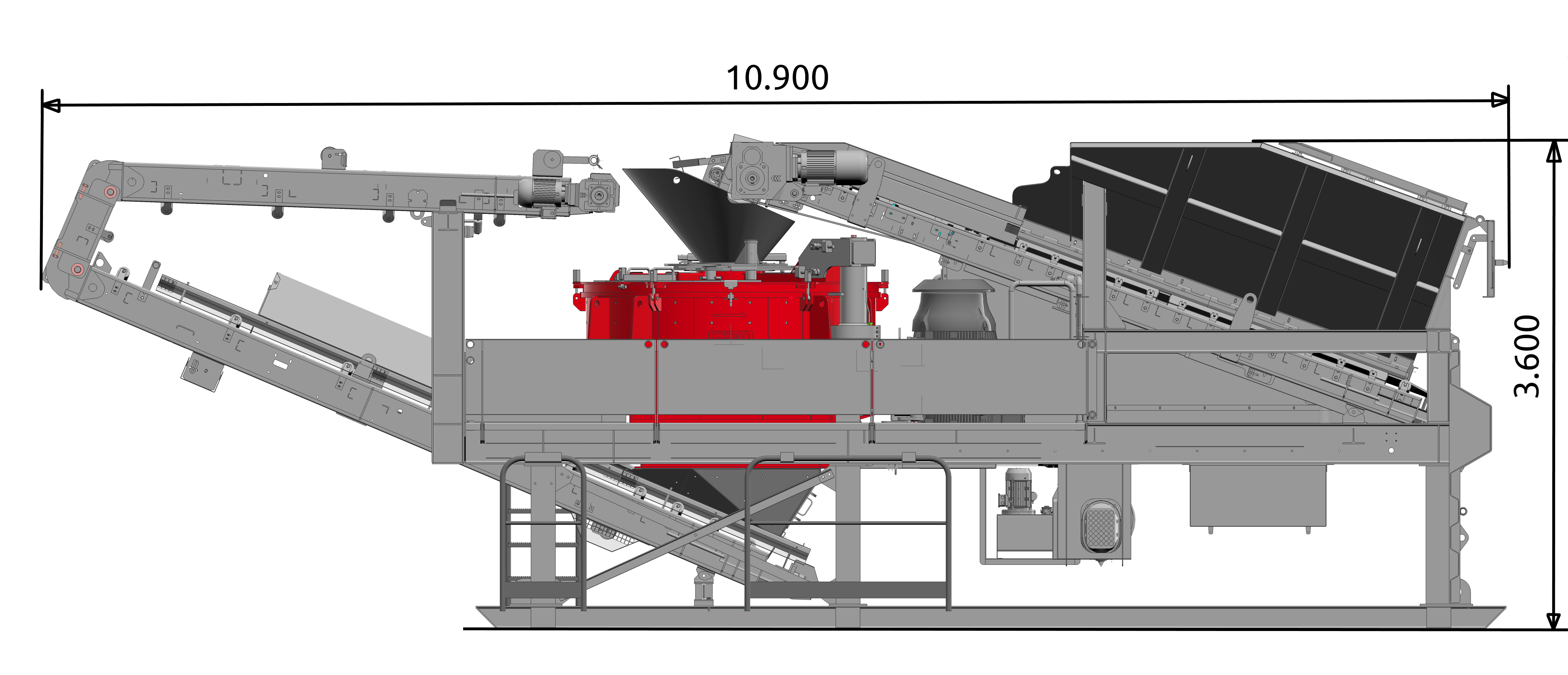

| DIMENSIONS Model V08 &V18 | Length | Width | Height | Weight |

|---|---|---|---|---|

| Operating status | 14.650 mm | 3.700 mm | 4.300 mm | 18.500 kg |

| Transport condition | 10.900 mm | 2.500 mm | 3.600 mm | 18.500 kg |

| TECHNICAL DATA Model V08 &V18 | |

|---|---|

| Feed performance | 90 t/h |

| Inlet crusher | 0 - 250 mm |

| Crusher drive | 132 kW, electric |

| Required grid feed-in capacity | 225 kVA |

| HARD FACTS Model V08 &V18 | |

|---|---|

| Feed material | Natural stone, square grain and round gravel |

| Task size | 0 - 40 mm 0 - 70 mm only with multipactor - Rotor V18 |

| Feed capacity max. | 90 t/h |

| Fina grain | 0 - 32 mm |

Fields of application

- For tertiary crushing of medium-hard to hard rock, such as limestone, dolomite, granite, diabase, gabbro, gravel, and to recycle asphalt, concrete, ....

- To make ill-formed grains cubic

- To produce nature-like rounded sands

- To increase the percentage of fines

- For abrasive materials

- To produce premium-quality products with superior grain form

- For a uniform grain-size distribution curve regardless of the wear condition of the main wear parts

- For selective crushing of feed materials with different qualities and / or hardness

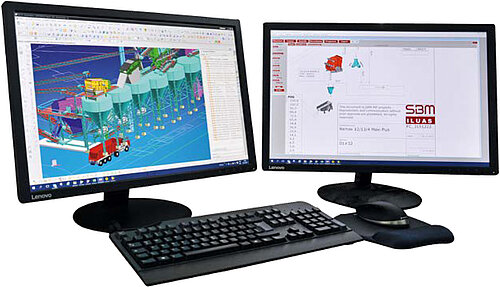

PROCESS ENGINEERING

SBM's sophisticated process technology is used to optimize the processing processes. To achieve the most cost-effective plant design, customer requirements are first specified. The material properties are then clarified, and the material can also be tested in our in-house laboratory. Based on this information, SBM experts design the plant and then use a calculation program to precisely determine the expected production quantities and product distributions.