Conveying technology

customised solutions that meet the most sophisticated demands

In the field Conveying technology SBM Mineral Processing offers a comprehensive product portfolio that has been specially developed for demanding tasks in the natural stones industry, sand and gravel production, building materials recycling, slag processing and ore dressing. With a wide choice of machine types and decades of experience, SBM focuses on one thing: you don't just get any machine, but you get exactly the right solution, individually tailored to your requirements.

Our expertise ranges from in-depth knowledge of raw materials and technical processes to innovative tools such as software-supported process simulations and our in-house laboratory for material analyses. Combined with first-class construction and the highest quality standards, conveying technology made by SBM assures maximum efficiency, reliability and cost-effectiveness - from planning to implementation.

SBM: Competence and expertise.

- QRF belt frame: galvanised steel pipe construction

- PBB-C belt frame: galvanised, edged steel plate construction

- PBB belt frame: galvanised, edged steel sheet construction

- PEB belt frame: galvanised, U-profile construction

- GTL belt frame: self-supporting framework construction, galvanised

- GTS belt frame: self-supporting framework construction, screwed, galvanised

- IB belt frame: galvanised I-beam construction

- Special constructions upon demand

Application areas :

- Output: up to2,00 t/h

- Width: 500 mm up to 2,000 mm

Length :

- From short conveyors to kilometre-long land conveyors

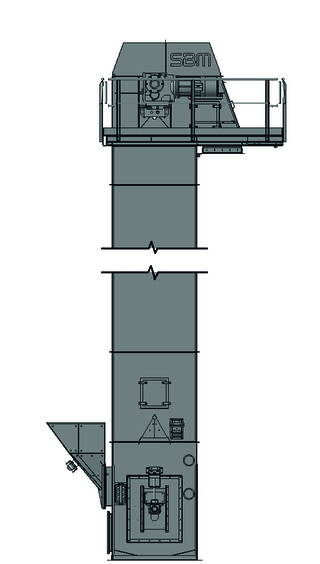

In line with market demands SBM Mineral Processing has developed a belt bucket elevator that is suitable to operate in very confined spaces and assures precisely separated conveying of raw materials.

Bucket width: 315 – 630 mm

Bucket types :

- Steel buckets

- Steel buckets with rubber bottom

- Rubber buckets

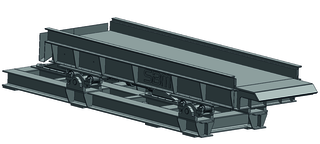

Dosing belts are extremely sturdy machines to convey, remove or dose mineral bulk materials from bunkers, stockpiles or silos with an output range of more than 1,000 t/h.

Equipment and construction features

- Galvanised construction

- Sealing by adjustable 2-lip rubber seal and end-to-end support of the belt on sliding plates

- Material flow controller with flag and external proximity switch

- Suitable for toughest applications to extract material from the feed hoppers of primary crushing plants

- Drive by 2 unbalance motors or unbalance drive unit with electric motor

- Suitable for dosed extraction from silos or subsurface extraction from stockpiles

- Options:

- Frequency converter

- Shock-absorbing wooden insert under the wear lining

- Chain and clapper curtains

- Dust cover

- Lining made of stainless steel or synthetic material

- Self-cleaning vibrating base (for sticky materials)