Natural stone

efficiency and sustainability

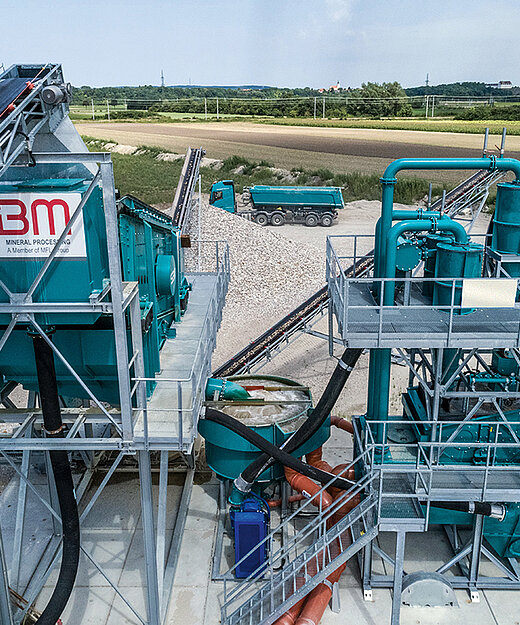

The processing of natural stones calls for precise technologies, tailor-made solutions and comprehensive expertise. SBM Mineral Processing GmbH combines years of experience in plant engineering with innovative concepts to offer high-performance and future-oriented complete solutions.

From project planning to turnkey plants, we offer everything from a single source: planning, design, engineering, manufacturing, control and electrics, assembly and start-up. Our plant systems are renowned worldwide for their efficiency and durability.

The processing of hard rock places special demands on mineral processing plants. With decades of experience and extensive expertise, SBM offers tailor-made solutions for plant engineering in this demanding field.

Our plants are specially designed to process even the hardest types of rock efficiently and reliably. We rely on pioneering technologies, sturdy designs and innovative processes to ensure excellent performance and maximum cost-effectiveness. By precisely coordinating all components - from hoppers and dosing equipment to crushing, conveying and screening technology - we guarantee optimum efficiency and a long working life.

The processing of hard rock is mainly used to produce:

- - Aggregates for concrete and asphalt

- - Gravel and stone chips

- - Defined aggregate mixes for road construction

The processing of sand and gravel involves special requirements in terms of technology and process design. The extracted material is often contaminated with impurities such as loam, clay, wood or coal, which must be removed prior to further processing. Individually adapted and sophisticated cleaning and separation processes are required to efficiently extract valuable raw materials.

SBM Mineral Processing offers customised complete solutions that allow a combination of different process steps to master these demanding challenges. Our stationary processing plants guarantee high performance and maximum efficiency in the processing of sand and gravel.

Our expertise in the field of sand & gravel includes:

- Individualised process design - solutions tailored to the specific requirements of the material for the separation of impurities such as loam, clay, wood or coal.

- Cleaning and separation - using high-performance equipment such as apron feeders, screening and washing processes for the specific separation of unwanted impurities.

- Impact crushers for high-quality stone chips - particularly suitable to produce stone chips and sand with optimised output quantities and high-quality final products.

SBM is YOUR partner to plan, design and implement process engineering sub-processes:

- Loosening

- Cleaning

- Refining, sorting

- Washing

- Dewatering

- Water circulation

- Crushing

- Grain optimisations

- Screening and classifying

- Landfilling

SBM offers comprehensive expertise in the field of limestone processing and provides complete solutions that cover the entire project cycle - from planning to production and start-up. Our plants for limestone, marl and other medium-hard rocks are characterised by maximum efficiency, precision and flexibility.

We pay particular attention to the process engineering design, which is tailored to the specific properties of the materials. With our proven SBM impact crushers, we offer optimum solutions for the primary, secondary and tertiary crushing steps and thus guarantee maximum efficiency and quality.

Special technologies for varying requirements:

- Discharge chutes and reciprocating feeders: Are installed below the feed hopper and guarantee steady material feed for medium-hard rock with a low quartz content.

- Apron feeders and roller grizzlies: Are used in primary crushing plants for materials with higher moisture content, sticky materials or impurities. These devices ensure efficient separation and pre-processing of the material.

SBM systems to process limestone and gypsum:

- Crushers

- Screening machines

- Discharge chutes

- Reciprocating feeders

- Apron feeders

- Roller grizzlies