Impact crushers SMR 10/5/4

Semi-mobile system

SBM impact crushers type SMR are impact crushers that are characterised by high throughput capacities and high crushing efficiency. Thanks to the symmetrical design of the machine and the rotation reversion of the crusher rotor, a uniform crushing product can be produced over the whole working life of the impact bars.

| DIMENSIONS | Length | Width | Height | Weight |

|---|---|---|---|---|

| Operating status | 14.300 mm | 3.500 mm | 4.600 mm | 25.500 kg |

| Transport condition | 10.150 mm | 2.600 mm | 3.700 mm | 25.500 kg |

| TECHNICAL DATA | |

|---|---|

| Feed performance | 80 t/h |

| Inlet crusher | 260 x 520 mm |

| Crusher drive | 110 kW |

| Diesel generator unit | 200 kVA |

| HARD FACTS | |

|---|---|

| Feed material | Natural rock, round gravel, oversized grains |

| Task size | 10 - 150 mm |

| Feed capacity max. | 80 t/h |

| Final grain | 0 - 32 mm |

| DRIVE SYSTEM | |

|---|---|

| Motor | CUMMINS B6.7 |

| Operating speed | 4-stufig |

| Tank capacity/Adblue | 350l / 38l |

| Generator | 200 kVA |

Fields of application

- To crush medium-hard to hard materials such as limestone, dolomite, gravel, hard coal and recycling materials without foreign matter

- For a high grain percentage in sand or stone chips

- For a low filler content in the sand

- For a uniform crushed product throughout the whole working life of the impact bars

- For abrasive materials thanks to the maximum utilisation rate of the wear parts

- To produce high-quality products with superior grain form

- Use in open or closed circuits when a very high crushing degree is required

- For tertiary crushing to achieve high-quality final products

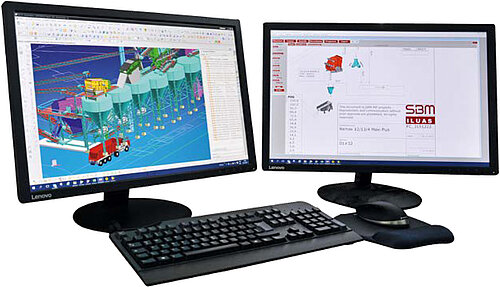

PROCESS ENGINEERING

Highly sophisticated SBM process engineering is used to optimise the mineral processing processes. To achieve the most economical plant design, the customer requirements are defined first. Then the material characteristics are assessed, whereby the material can also be analysed in the in-house laboratory. On this basis the SBM experts subsequently plan the plant and use a calculation programme to specify the expected production quantities and product distributions.