Crushing technology

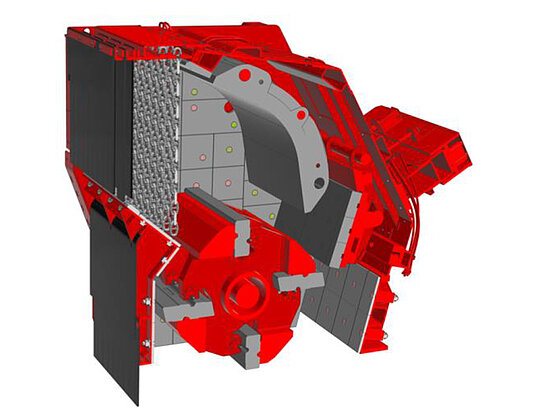

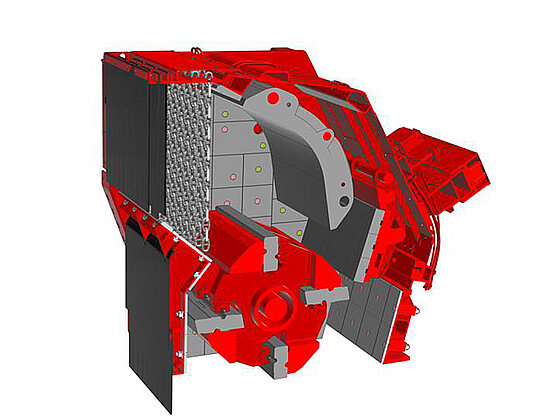

SBM is setting high standards in crushing technology: Our sturdy and durable crushers combine innovative impact crusher and jaw crusher technology with an optimised crushing chamber geometry to maximise efficiency. High throughput capacity, flexibility and reliability make them the first choice for natural stones, recycling materials and the most challenging applications.

Fields of applications

- To crush medium-hard to hard and abrasive materials

- For all primary crushing applications in mineral processing and mining

- Suitable for large feed sizes due to optimised intake geometry

- Suitable for abrasive materials due to customised crushing chamber geometry

- For a low percentage of fines in the final product

- For recycling with a high crushing rate

| Type | Feed size class di - Di (mm) | Feed size maximal max. (mm) | Throughput capacity (tph) | Drive power (kW) | Reduction ratio up to | Typical products (mm) |

|---|---|---|---|---|---|---|

| STE 90-60 | 0 – 550 | 800 x 550 x 400 | 25 - 240 | 75 - 90 | 1 : 7 | 0 – 175; 0 - 50 |

| STE 100-65 | 0 - 600 | 900 x 600 x 400 | 50 - 290 | 90 - 132 | 1 : 7 | 0 – 200; 0 - 75 |

| STE 108-75 | 0 - 700 | 1.000 x 700 x 400 | 100 - 560 | 132 | 1 : 7 | 0 – 250; 0 - 75 |

| STE 120-100 | 0 – 950 | 1.100 x 950 x 600 | 250 - 700 | 132 - 160 | 1 : 7 | 0 – 350; 0 - 100 |

| STE 140-110 | 0 – 1.050 | 1.300 x 1.050 x 700 | 300 - 800 | 160 | 1 : 7 | 0 – 400; 0 - 175 |

| STE 160-130 | 0 – 1.250 | 1.400 x 1.250 x 900 | 400 – 1.000 | 200 | 1 : 7 | 0 – 400; 0 - 150 |

| Type | Inlet opening w x l (mm) | Rotor speed (Upm) | Gap css in (mm) | Jaw spacing (mm) | Weight (kg) | Airflow rate |

|---|---|---|---|---|---|---|

| STE 90-60 | 900 x 600 | 270 - 320 | 35 - 140 | 45 | 10.300 | 2.000 |

| STE 100-65 | 1.000 x 650 | 270 - 320 | 50 - 150 | 55 | 16.200 | 2.000 |

| STE 108-75 | 1.080 x 750 | 270 - 320 | 50 – 280 | 66 | 28.200 | 2.500 |

| STE 120-100 | 1.200 x 1.000 | 200 - 230 | 100 - 300 | 87 | 40.000 | 3.000 |

| STE 140-110 | 1.400 x 1.100 | 200 - 230 | 160 - 320 | 120 | 49.000 | 3.500 |

| STE 160-130 | 1.600 x 1.300 | 200 - 230 | 130 - 340 | 120 | 71.500 | 4.000 |

| Type | Transport volume (m3) | Length (mm) | Width (mm) | Height (mm) | Gap adjustment |

|---|---|---|---|---|---|

| STE 90-60 | 7,6 | 2.464 | 1.634 | 1.878 | hydro-mechanical |

| STE 100-65 | 12,3 | 2.940 | 1.934 | 2.160 | hydro-mechanical |

| STE 108-75 | 26 | 4.308 | 2.115 | 2.851 | fully hydraulic |

| STE 120-100 | 27,1 | 3.561 | 2.212 | 3.443 | hydro-mechanical |

| STE 140-110 | 3.604 | 2.570 | 3.600 | hydro-mechanical | |

| STE 160-130 | 3.792 | 2.770 | 4.496 | hydro-mechanical |

| Gap width css in (mm) | 300 | 250 | 200 | 150 | 100 | 50 |

|---|---|---|---|---|---|---|

| STE 90-60 | 240 | 160 | 95 | |||

| STE 100-65 | 290 | 200 | 110 | |||

| STE 108-75 | 560 | 460 | 350 | 240 | 120 | |

| STE 120-100 | 700 | 630 | 510 | 400 | 280 | |

| STE 140-110 | 800 | 670 | 600 | 460 | ||

| STE 160-130 | 1.000 | 770 | 690 | 530 |

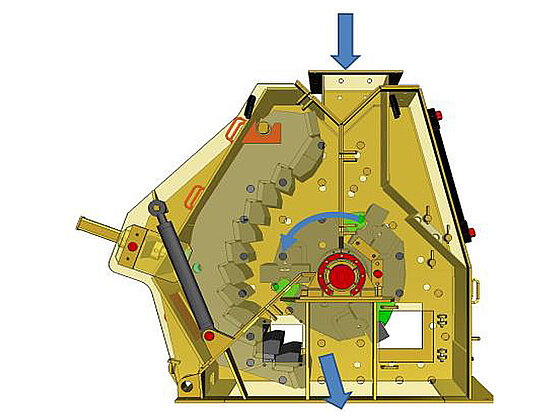

Fields of application

- To crush soft to hard materials such as limestone, dolomite, gravel, hard coal, ...

- For primary crushing with crushers type RHS

- For secondary crushing with crushers type RHSK

- For applications requiring a high percentage of fines and little oversize grain, thanks to the optional grinding path

- To produce high-quality products with very good grain form thanks to the optional grinding path

- For abrasive materials due to the high utilisation factor of the wear parts

- For operation in open or closed circuit when a very high crushing rate is required

| Type | Feed size class di-Di (mm) | Fedd size max. (mm) | Throughput capacity (tph) | Drive capacity (kW) | Reduction ratio up to | Typical products (mm) |

|---|---|---|---|---|---|---|

| RHS 13-13-4 | 0 – 1.000 | 1.200 x 1.000 x 500 | 200 - 325 | 132 - 200 | 1 : 15 | 0 – 32; 0 – 56 |

| RHSK 13-13-4 | 0 - 300 | 500 x 300 x 200 | 200 - 325 | 132 - 200 | 1 : 15 | 0 – 22; 0 – 32 |

| RHS 13-16-4 | 0 – 1.000 | 1.200 x 1.000 x 500 | 250 - 400 | 200 - 355 | 1 : 15 | 0 – 32; 0 – 56 |

| RHSK 13-16-4 | 0 - 300 | 500 x 300 x 200 | 250 - 400 | 200 -355 | 1 : 15 | 0 – 22; 0 – 32 |

| RHS 13-21-4 | 0 – 1.000 | 1.200 x 1.000 x 500 | 350 - 600 | 315 - 500 | 1 : 15 | 0 – 32; 0 – 56 |

| RHSK 13-21-4 | 0 - 300 | 500 x 300 x 200 | 350 - 600 | 315 - 500 | 1 : 15 | 0 – 22; 0 – 32 |

| RHS 16-19-4 | 0 – 1.200 | 1.400 x 1.200 x 500 | 500 - 800 | 400 - 800 | 1 : 12 | 0 – 63; 0 – 200 |

| RHS 16-23-4 | 0 - 1.200 | 1.400 x 1.200 x 500 | 600 – 1.000 | 500 - 1.000 | 1 : 12 | 0 – 63; 0 – 200 |

| Type | Inlet opening w x l (mm) | Rotor diameter (mm) | Rotor speed (Upm) | Rotor velocity (m/s) | Impact bar weight SF/SSSL (kg) | Weight (kg) | Airflow rate (m3ph) |

|---|---|---|---|---|---|---|---|

| RHS 13-13-4 | 1.260 x 1.040 | 1.280 | 450 - 666 | 30 -44 | 235 / 360 | 17.500 | 10.000 |

| RHSK 13-13-4 | 1.260 x 530 | 1.280 | 450 - 660 | 30 -44 | 235 / 360 | 17.800 | 10.000 |

| RHS 13-16-4 | 1.540 x 1.040 | 1.280 | 450 - 666 | 30 -44 | 300 / 510 | 20.500 | 12.000 |

| RHSK 13-16-4 | 1.540 x 460 | 1.280 | 450 - 660 | 30 -44 | 300 / 510 | 21.500 | 12.000 |

| RHS 13-21-4 | 2.020 x 1.040 | 1.280 | 450 - 660 | 30 -44 | 480 / - | 25.250 | 15.000 |

| RHSK 13-21-4 | 2.020 x 600 | 1.280 | 450 - 660 | 30 -44 | 480 / - | 25.250 | 15.000 |

| RHS 16-19-4 | 1.860 x 1.430 | 1.600 | 350 - 520 | 30 -44 | 470 / - | 40.100 | 15.000 |

| RHS 16-23-4 | 2.260 x 1.380 | 1.600 | 350 - 520 | 30 -44 | 570 / - | 48.100 | 18.000 |

| Type | Transport volume (m3) | Length (mm) | Width (mm) | Height(mm) | Adjustment of the apron |

|---|---|---|---|---|---|

| RHS 13-13-4 | 19,0 | 3.040 | 2.250 | 2.990 | hydro-mechanical |

| RHSK 13-13-4 | 19,0 | 3.040 | 2.250 | 2.990 | hydro-mechanical |

| RHS 13-16-4 | 20,6 | 3.026 | 2.631 | 2.591 | fully hydraulic |

| RHSK 13-16-4 | 20,5 | 3.026 | 2.608 | 2.591 | hydro-mechanical |

| RHS 13-21-4 | 29,5 | 3.040 | 3.610 | 2.684 | hydro-mechanical |

| RHSK 13-21-4 | 28,6 | 3.040 | 3.561 | 2.635 | hydro-mechanical |

| RHS 16-19-4 | 49,8 | 3.607 | 3.468 | 3.975 | hydro-mechanical |

| RHS 16-23-4 | 54,4 | 3.547 | 4.073 | 3.733 | hydro-mechanical |

| Gap width (mm) | 150 | 125 | 100 | 75 | 50 |

|---|---|---|---|---|---|

| RHS 13-13-4 | 325 | 300 | 275 | 250 | 225 |

| RHSK 13-13-4 | 325 | 300 | 275 | 250 | 225 |

| RHS 13-16-4 | 400 | 375 | 350 | 325 | 300 |

| RHSK 13-16-4 | 400 | 375 | 350 | 325 | 300 |

| RHS 13-21-4 | 600 | 550 | 500 | 450 | 400 |

| RHSK 13-21-4 | 600 | 550 | 500 | 450 | 400 |

| RHS 16-19-4 | 800 | 700 | 600 | ||

| RHS 16-23-4 | 1.000 | 850 | 700 |

Fields of application

- For recycling applications such as construction debris, concrete demolition with reinforcements, and asphalt.

- For the crushing of soft to medium-hard materials, such as limestone, dolomite, and coal.

- For primary crushing of medium-hard natural stone.

- For primary and secondary crushing of recycling materials, including those with reinforcements.

- For wear-intensive materials due to very good utilization rates of the wear parts.

- For the production of quality products with a high reduction ratio.

| Type | Feed size class di-Di (mm) | Feed size max. (mm) | Throughput capacity (tph) | Drive capacity (kW) | Reduction ratio up to | Typical products (mm) |

|---|---|---|---|---|---|---|

| RCI 09-10-4 | 0 – 500 | 800 x 500 x 400 | 100 - 150 | 90 - 100 | 1 : 15 | 0 – 32; 0 - 56 |

| RCI 11-11-4 | 0 - 600 | 900 x 600 x 400 | 125 - 200 | 110 - 132 | 1 : 15 | 0 – 32; 0 - 56 |

| RCI 12-13-4 | 0 - 700 | 1.000 x 700 x 400 | 200 - 300 | 132 - 160 | 1 : 15 | 0 – 45; 0 - 90 |

| RCI 13-14-4 | 0 – 950 | 1.100 x 800 x 400 | 300 - 500 | 250 - 315 | 1 : 15 | 0 – 45; 0 - 90 |

| Type | Inlet opening w x l (mm) | Rotor diameter (mm) | Rotor speed (Upm) | Rotor velocity (m/s) | Weight (kg) | Airflow rate (m3ph) |

|---|---|---|---|---|---|---|

| RCI 09-10-4 | 960 x 670 | 912 | 629 - 838 | 30 - 40 | 6.000 | 4.000 |

| RCI 11-11-4 | 1.040 x 700 | 1.060 | 541 - 721 | 30 - 40 | 9.300 | 5.000 |

| RCI 12-13-4 | 1.270 x 800 | 1.160 | 494 - 659 | 30 - 40 | 12.300 | 6.000 |

| RCI 13-14-4 | 1.380 x 985 | 1.300 | 441 - 588 | 30 - 40 | 16.500 | 10.000 |

| Type | Transport volume (m3) | Length (mm) | Width (mm) | Height (mm) | Adjustment of the apron |

|---|---|---|---|---|---|

| RCI 09-10-4 | 6,5 | 1.933 | 1.795 | 1.878 | hydro-mechanical |

| RCI 11-11-4 | 12,3 | 2.230 | 2.082 | 2.049 | hydro-mechanical |

| RCI 12-13-4 | 26 | 2.543 | 2.285 | 2.162 | hydro-mechanical |

| RCI 13-14-4 | 27,1 | 2.975 | 2.417 | 2.595 | hydro-mechanical |

| Gap width css in (mm) | 150 | 125 | 100 | 75 | 50 |

|---|---|---|---|---|---|

| RCI 09-10-4 | 150 | 125 | |||

| RCI 11-11-4 | 200 | 175 | 150 | ||

| RCI 12-13-4 | 300 | 275 | 250 | 225 | |

| RCI 13-14-4 | 500 | 450 | 400 | 350 | 300 |

SBM impact crushers type SMR are high-tech impact crushers that are characterised by high throughput rates and excellent crushing efficiency. Thanks to the symmetrical design of the machine and the rotation reversion of the crusher rotor, a uniform crushing product can be produced over the whole working life of the impact bars.

SYSTEM DATA

Fields of applications

- To crush medium-hard to hard materials such as limestone, dolomite, gravel, hard coal and recycling materials without foreign materials

- For a high percentage of grain in sand or stone chips

- For a low filler content in the sand

- To obtain a uniform crushed product over the working life of the impact bars

- For abrasive materials due to the maximum utilisation factor of the wear parts

- To produce high-quality products with very good grain form

- For operation in open or closed circuit when a very high crushing rate is required

- In tertiary crushing to obtain high-quality final products

| Type | Feed size class di-Di (mm) | Feed size max. (mm) | Throughput capacity (tph) | Drive capacity (kW) | Reduction ratio up to | Typical products (mm) |

|---|---|---|---|---|---|---|

| SMR 10-05-4 | 0 – 125 | 150 x 125 x 100 | 50 - 100 | 55 - 132 | 1 : 15 | 0 – 22; 0 – 32 |

| SMR 10-10-4 | 0 - 125 | 150 x 125 x 100 | 100 -200 | 110 - 250 | 1 : 15 | 0 – 22; 0 – 32 |

| SMR 13-07-4 | 0 – 125 | 200 x 175 x 150 | 100 – 250 | 132 - 250 | 1 : 15 | 0 – 22; 0 – 32 |

| Type | Inlet opening w x l (mm) | Rotor diameter (mm) | Rotor speed (Upm) | Rotor velocity (m/s) | Impact bar weight | Weight (kg) | Airflow rate |

|---|---|---|---|---|---|---|---|

| SMR 10-05-4 | 515 x 260 | 1.080 | 500 - 900 | 30 -50 | 4 x 100 | 8.000 | 2.900 |

| SMR 10-10-4 | 1.015 x 260 | 1.080 | 500 - 900 | 30 -50 | 4 x 200 | 12.100 | 4.700 |

| SMR 13-07-4 | 640 x 400 | 1.300 | 400 - 750 | 30 -50 | 4 x 185 | 14.900 | 6.000 |

| Type | Transport volume (m3) | Length (mm) | Width (mm) | Height (mm) | Adjustments of the apron |

|---|---|---|---|---|---|

| SMR 10-05-4 | 10,8 | 3.255 | 1.580 | 2.100 | mechanical |

| SMR 10-05-4 | 11,5 | 3.450 | 1.580 | 2.100 | hydraulic |

| SMR 10-10-4 | 14,2 | 3.255 | 2.070 | 2.100 | hydraulic |

| SMR 10-10-4 | 15,1 | 3.455 | 2.070 | 2.100 | hydraulic |

| SMR 13-07-4 | 22,2 | 4.270 | 2.000 | 2.600 | hydraulic |

| Gap width (mm) | 60 | 50 | 40 | 30 | 02 | 10 |

|---|---|---|---|---|---|---|

| SMR 10-05-4 | 100 | 95 | 90 | 70 | 60 | 50 |

| SMR 10-10-4 | 200 | 190 | 180 | 140 | 120 | 100 |

| SMR 13-07-4 | 200 | 190 | 180 | 140 | 120 | 100 |

Fields of applications

- To crush medium-hard materials such as limestone, dolomite, gravel, hard coal, phosphate, ...

- For oversize crushing of smaller quantities

- For a low filler content in the sand

- For abrasive materials due to a high utilisation factor of wear parts

- To produce high-quality products with a good grain form

- For operation in open or closed circuit when a very high crushing rate is required

- In tertiary crushing to obtain high-quality end products

| Type | Feed size cla ss di-Di (mm) | Feed size max. (mm) | Throughput capacity (tph) | Drive capacity (kW) | Reduction ratio up to | Typical products (mm) |

|---|---|---|---|---|---|---|

| CI 85-60-3 | 0 – 125 | 150 x 125 x 100 | 50 - 75 | 55 - 75 | 1 : 15 | 0 – 22; 0 - 32 |

| Type | Inlet opening w x l (mm) | Rotor diameter (mm) | Rotor speed (Upm) | Rotor velocity (m/s) | Impact bar weight (kg) | Weight | Airflow rate |

|---|---|---|---|---|---|---|---|

| CI 85-60-3 | 620 x 270 | 865 | 650 - 900 | 30 - 45 | 3 x 104 | 4.900 | 2.500 |

| Type | Transport volume (m3) | Length (mm) | Width (mm) | Height (mm) | Gap adjustments |

|---|---|---|---|---|---|

| CI 85-60-3 | 6,1 | 2.266 | 1.496 | 1.800 | mechanical |

| Gap width (mm) | 60 | 50 | 40 | 30 | 20 | 15 |

|---|---|---|---|---|---|---|

| CI 85-60-3 | 75 | 65 | 55 | 45 | 35 | 30 |

| Zerkleinerung von: | Mittelhartem bis hartem Gestein |

| Aufgabegröße: | 0 - 250 mm 300 x 250 x 200 mm |

| Abgabemenge: | 50 - 90 tph |

| Masse: | 4.500 - 5.150 kg |

Fields of application

- To crush medium-hard to hard materials

- For oversize crushing of smaller quantities

- For a low filler content in the sand

- For abrasive materials due to a high utilisation factor of wear parts

- To produce high-quality products with a good grain form

- For operation in open or closed circuit when a very high crushing rate is required

| Type | Feed size up to (mm) | Throughput capacity (t/h) | Rotor diameter (mm) |

|---|---|---|---|

| 8/5/3 | 200 | 50 - 70 | 800 |

| 8/7/3 | 250 | 60 - 90 | 800 |

Fields of applications

- For recycling applications such as construction debris, concrete demolition with reinforcements, and asphalt.

- For the crushing of soft to medium-hard materials, such as limestone, dolomite, and coal.

- For primary crushing of medium-hard natural stone.

- For primary and secondary crushing of recycling materials, including those with reinforcements.

- For wear-intensive materials due to very good utilization rates of the wear parts.

- For the production of quality products with a high reduction ratio.

| Type | Feed size class di-Di (mm) | Feed size max. (mm) | Throughput capacity (tph) | Drive capacity (kW) | Reduction ratio up to | Typical products (mm) |

|---|---|---|---|---|---|---|

| RCI 09-10-4 | 0 – 500 | 800 x 500 x 400 | 100 - 150 | 90 - 110 | 1 : 15 | 0 – 32; 0 - 56 |

| RCI 11-11-4 | 0 - 600 | 900 x 600 x 400 | 125 - 200 | 110 - 132 | 1 : 15 | 0 – 32; 0 - 56 |

| RCI 12-13-4 | 0 - 700 | 1.000 x 700 x 400 | 200 - 300 | 132 - 160 | 1 : 15 | 0 – 45; 0 - 90 |

| RCI 13-14-4 | 0 – 950 | 1.100 x 800 x 400 | 300 - 500 | 250 - 315 | 1 : 15 | 0 – 45; 0 - 90 |

| Type | Inlet opening w x l (mm) | Rotor diameter (mm) | Rotor speed (Upm) | Rotor velocity (m/s) | Weight (kg) | Airflow rate (m3ph) |

|---|---|---|---|---|---|---|

| RCI 09-10-4 | 960 x 670 | 912 | 629 - 838 | 30 - 40 | 6.000 | 4.000 |

| RCI 11-11-4 | 1.040 x 700 | 1.060 | 541 - 721 | 30 - 40 | 9.300 | 5.000 |

| RCI 12-13-4 | 1.270 x 800 | 1.160 | 494 - 659 | 30 - 40 | 12.300 | 6.000 |

| RCI 13-14-4 | 1.380 x 985 | 1.300 | 441 - 588 | 30 - 40 | 16.500 | 10.000 |

| Type | Transport volume (m3) | Length (mm) | Width (mm) | Height (mm) | Adjustment of the apron |

|---|---|---|---|---|---|

| RCI 09-10-4 | 6,5 | 1.933 | 1.795 | 1.878 | hydro-mechanical |

| RCI 11-11-4 | 9,5 | 2.230 | 2.082 | 2.049 | hydro-mechanical |

| RCI 12-13-4 | 12,6 | 2.543 | 2.285 | 2.162 | hydro-mechanical |

| RCI 13-14-4 | 18,7 | 2.975 | 2.417 | 2.595 | hydro-mechanical |

| Spaltweite css in (mm) | 150 | 125 | 100 | 75 | 50 | 25 |

|---|---|---|---|---|---|---|

| RCI 09-10-4 | 150 | 125 | 100 | |||

| RCI 11-11-4 | 200 | 175 | 150 | 125 | ||

| RCI 12-13-4 | 300 | 275 | 250 | 225 | 200 | |

| RCI 13-14-4 | 500 | 450 | 400 | 350 | 300 | 250 |

Fields of applications

- To crush soft to hard materials such as limestone, dolomite, gravel, hard coal, ...

- For primary crushing with crushers type RHS

- For secondary crushing with crushers type RHSK

- For applications requiring a high percentage of fines and little oversize grain, thanks to the optional grinding path

- To produce high-quality products with very good grain form thanks to the optional grinding path

- For abrasive materials due to the high utilisation factor of the wear parts

- For operation in open or closed circuit when a very high crushing rate is required

| Type | Feed size class di-Di (mm) | Fedd size max. (mm) | Throughput capacity (tph) | Drive capacity (kW) | Reduction ratio up to | Typical products (mm) |

|---|---|---|---|---|---|---|

| RHS 13-13-4 | 0 – 1.000 | 1.200 x 1.000 x 500 | 200 - 325 | 132 - 200 | 1 : 15 | 0 – 32; 0 – 56 |

| RHSK 13-13-4 | 0 - 300 | 500 x 300 x 200 | 200 - 325 | 132 - 200 | 1 : 15 | 0 – 22; 0 – 32 |

| RHS 13-16-4 | 0 – 1.000 | 1.200 x 1.000 x 500 | 250 - 400 | 200 - 355 | 1 : 15 | 0 – 32; 0 – 56 |

| RHSK 13-16-4 | 0 - 300 | 500 x 300 x 200 | 250 - 400 | 200 -355 | 1 : 15 | 0 – 22; 0 – 32 |

| RHS 13-21-4 | 0 – 1.000 | 1.200 x 1.000 x 500 | 350 - 600 | 315 - 500 | 1 : 15 | 0 – 32; 0 – 56 |

| RHSK 13-21-4 | 0 - 300 | 500 x 300 x 200 | 350 - 600 | 315 - 500 | 1 : 15 | 0 – 22; 0 – 32 |

| RHS 16-19-4 | 0 – 1.200 | 1.400 x 1.200 x 500 | 500 - 800 | 400 - 800 | 1 : 12 | 0 – 63; 0 – 200 |

| RHS 16-23-4 | 0 - 1.200 | 1.400 x 1.200 x 500 | 600 – 1.000 | 500 - 1.000 | 1 : 12 | 0 – 63; 0 – 200 |

| Type | Inlet opening w x l (mm) | Rotor diameter (mm) | Rotor speed (Upm) | Rotor velocity (m/s) | Impact bar weight SF/SSSL (kg) | Weight (kg) | Airflow rate (m3ph) |

|---|---|---|---|---|---|---|---|

| RHS 13-13-4 | 1.260 x 1.040 | 1.280 | 450 - 666 | 30 -44 | 235 / 360 | 17.500 | 10.000 |

| RHSK 13-13-4 | 1.260 x 530 | 1.280 | 450 - 660 | 30 -44 | 235 / 360 | 17.800 | 10.000 |

| RHS 13-16-4 | 1.540 x 1.040 | 1.280 | 450 - 666 | 30 -44 | 300 / 510 | 20.500 | 12.000 |

| RHSK 13-16-4 | 1.540 x 460 | 1.280 | 450 - 660 | 30 -44 | 300 / 510 | 21.500 | 12.000 |

| RHS 13-21-4 | 2.020 x 1.040 | 1.280 | 450 - 660 | 30 -44 | 480 / - | 25.250 | 15.000 |

| RHSK 13-21-4 | 2.020 x 600 | 1.280 | 450 - 660 | 30 -44 | 480 / - | 25.250 | 15.000 |

| RHS 16-19-4 | 1.860 x 1.430 | 1.600 | 350 - 520 | 30 -44 | 470 / - | 40.100 | 15.000 |

| RHS 16-23-4 | 2.260 x 1.380 | 1.600 | 350 - 520 | 30 -44 | 570 / - | 48.100 | 18.000 |

| Type | Transport volume (m3) | Length (mm) | Width (mm) | Height(mm) | Adjustment of the apron |

|---|---|---|---|---|---|

| RHS 13-13-4 | 19,0 | 3.040 | 2.250 | 2.990 | hydro-mechanical |

| RHSK 13-13-4 | 19,0 | 3.040 | 2.250 | 2.990 | hydro-mechanical |

| RHS 13-16-4 | 20,6 | 3.026 | 2.631 | 2.591 | fully hydraulic |

| RHSK 13-16-4 | 20,5 | 3.026 | 2.608 | 2.591 | hydro-mechanical |

| RHS 13-21-4 | 29,5 | 3.040 | 3.610 | 2.684 | hydro-mechanical |

| RHSK 13-21-4 | 28,6 | 3.040 | 3.561 | 2.635 | hydro-mechanical |

| RHS 16-19-4 | 49,8 | 3.607 | 3.468 | 3.975 | hydro-mechanical |

| RHS 16-23-4 | 54,4 | 3.547 | 4.073 | 3.733 | hydro-mechanical |

| Gap width (mm) | 150 | 125 | 100 | 75 | 50 |

|---|---|---|---|---|---|

| RHS 13-13-4 | 325 | 300 | 275 | 250 | 225 |

| RHSK 13-13-4 | 325 | 300 | 275 | 250 | 225 |

| RHS 13-16-4 | 400 | 375 | 350 | 325 | 300 |

| RHSK 13-16-4 | 400 | 375 | 350 | 325 | 300 |

| RHS 13-21-4 | 600 | 550 | 500 | 450 | 400 |

| RHSK 13-21-4 | 600 | 550 | 500 | 450 | 400 |

| RHS 16-19-4 | 800 | 700 | 600 | ||

| RHS 16-23-4 | 1.000 | 850 | 700 |

SBM impact crushers type SMR are high-tech impact crushers that are characterised by high throughput rates and excellent crushing efficiency. Thanks to the symmetrical design of the machine and the rotation reversion of the crusher rotor, a uniform crushing product can be produced over the whole working life of the impact bars.

SYSTEM DATA

Fields of applications

- To crush medium-hard to hard materials such as limestone, dolomite, gravel, hard coal and recycling materials without foreign materials

- For a high percentage of grain in sand or stone chips

- For a low filler content in the sand

- To obtain a uniform crushed product over the working life of the impact bars

- For abrasive materials due to the maximum utilisation factor of the wear parts

- To produce high-quality products with very good grain form

- For operation in open or closed circuit when a very high crushing rate is required

- In tertiary crushing to obtain high-quality final products

| Type | Feed size class di-Di(mm) | Feed size max. (mm) | Throughput capacity (tph) | Drive capacity (kW) | Reducation ratio up to | Typical products (mm) |

|---|---|---|---|---|---|---|

| SMR 10-05-4 | 0 – 125 | 150 x 125 x 100 | 50 - 100 | 55 - 132 | 1 : 15 | 0 – 22; 0 – 32 |

| SMR 10-10-4 | 0 - 125 | 150 x 125 x 100 | 100 -200 | 110 - 250 | 1 : 15 | 0 – 22; 0 – 32 |

| SMR 13-07-4 | 0 – 125 | 200 x 175 x 150 | 100 – 250 | 132 - 250 | 1 : 15 | 0 – 22; 0 – 32 |

| Type | Inlet opening w x l (mm) | Rotor diameter (mm) | Rotor Speed (Upm) | Rotor velocity (m/s) | Imapct bar weight | Weight (kg) | Airflow rate |

|---|---|---|---|---|---|---|---|

| SMR 10-05-4 | 515 x 260 | 1.080 | 500 - 900 | 30 -50 | 4 x 100 | 8.000 | 2.900 |

| SMR 10-10-4 | 1.015 x 260 | 1.080 | 500 - 900 | 30 -50 | 4 x 200 | 12.100 | 4.700 |

| SMR 13-07-4 | 640 x 400 | 1.300 | 400 - 750 | 30 -50 | 4 x 185 | 14.900 | 6.000 |

| Type | Transport volume (m3) | Length (mm) | Width (mm) | Height (mm) | Adjustment of the apron |

|---|---|---|---|---|---|

| SMR 10-05-4 | 10,8 | 3.255 | 1.580 | 2.100 | mechanical |

| SMR 10-05-4 | 11,5 | 3.450 | 1.580 | 2.100 | hydraulic |

| SMR 10-10-4 | 14,2 | 3.255 | 2.070 | 2.100 | hydraulic |

| SMR 10-10-4 | 15,1 | 3.455 | 2.070 | 2.100 | hydraulic |

| SMR 13-07-4 | 22,2 | 4.270 | 2.000 | 2.600 | hydraulic |

| Gap width (mm) | 60 | 50 | 40 | 30 | 02 | 10 |

|---|---|---|---|---|---|---|

| SMR 10-05-4 | 100 | 95 | 90 | 70 | 60 | 50 |

| SMR 10-10-4 | 200 | 190 | 180 | 140 | 120 | 100 |

| SMR 13-07-4 | 200 | 190 | 180 | 140 | 120 | 100 |

Fields of applications

- For tertiary crushing of medium-hard to hard natural stones

- To make ill-formed grains cubic

- To produce nature-like rounded sands

- To increase the percentage of fines

- For abrasive materials

- To produce high-quality products with superior grain form

- For a uniform grain size distribution curve regardless of the wear condition of the main wear parts

- For selective crushing of feed materials with different qualities and/or hardness

| Type | Feed size class di-Di (mm) | Feed size max. (mm) | Throughput capacity (tph) | Drive capacity (kW) | Reduction ratio up to | Typical products (mm) |

|---|---|---|---|---|---|---|

V 08 | 0 – 35 | 45 x 35 x 25 | 30 - 85 | 70 - 160 | 1 : 4 | 0 - 4; 0- 22 |

V 10 | 0 – 35 | 45 x 35 x 25 | 50 - 140 | 90 - 250 | 1 : 4 | 0 - 4; 0- 22 |

V 10-H | 0 – 35 | 45 x 35 x 25 | 50 - 160 | 132 - 250 | 1 : 4 | 0 - 4; 0- 22 |

| Type | Inlet opening w x l (mm) | Rotor diameter (mm) | Rotor velocity (m/s) | Impact bar weight | Weight (kg) | Airflow rate |

|---|---|---|---|---|---|---|

V 08 | 250 | 800 | 40 -80 | 1.450 - 1.950 | 6.100 | 4.900 |

V 10 | 280 | 1.000 | 40 -80 | 1.150 - 1.550 | 8.200 | 5.200 |

V 10-H | 280 | 1.000 | 40 -80 | 1.150 - 1.550 | 8.600 | 5.200 |

Type | Transport volume (m3) | Length (mm) | Width (mm) | Height (mm) | Adjustment of the apron |

|---|---|---|---|---|---|

V 08 | 13,8 | 3.340 | 2.335 | 1.770 | mechanical / hydraulic |

| V 10 | 20,1 | 3.757 | 2.604 | 2.060 | mechanical / hydraulic |

V 10-H | 20,1 | 3.757 | 2.604 | 2.060 | mechanical / hydraulic |

Fields of applications

- To crush medium-hard materials such as limestone, dolomite, gravel, hard coal, phosphate, ...

- For oversize crushing of smaller quantities

- For a low filler content in the sand

- For abrasive materials due to a high utilisation factor of wear parts

- To produce high-quality products with a good grain form

- For operation in open or closed circuit when a very high crushing rate is required

- In tertiary crushing to obtain high-quality end products

| Type | Feed size class di-Di (mm) | Feed size max. (mm) | Throughput capacity (tph) | Drive capacity (kW) | Reducation ratio up to | Typical products (mm) |

|---|---|---|---|---|---|---|

| CI 85-60-3 | 0 – 125 | 150 x 125 x 100 | 50 - 75 | 55 - 75 | 1 : 15 | 0 – 22; 0 - 32 |

| Type | Inlet opening w x l (mm) | Rotor diameter (mm) | Rotor speed (Upm) | Rotor velocity (m/s) | Impact bar weight (kg) | Weight | Airflow rate |

|---|---|---|---|---|---|---|---|

| CI 85-60-3 | 620 x 270 | 865 | 650 - 900 | 30 - 45 | 3 x 104 | 4.900 | 2.500 |

| Type | Transport volume (m3) | Length (mm) | Width (mm) | Height (mm) | Adjustment of the apron |

|---|---|---|---|---|---|

| CI 85-60-3 | 6,1 | 2.266 | 1.496 | 1.800 | mechanic |

| Gap (mm) | 60 | 50 | 40 | 30 | 20 | 15 |

|---|---|---|---|---|---|---|

| CI 85-60-3 | 75 | 65 | 55 | 45 | 35 | 30 |