LIMESTONE

0/550 auf 0/180

Product performance: 250 t/h

Diesel consumption: 15 l/h

Crushing jaws: MNMO

RIVER GRAVEL

0/400 auf 0/90

Product performance: 160 t/h

Diesel consumption: 14 l/h

Crushing jaws: MN

CONCRETE & BRICK

0/500 auf 0/90

Product performance: 170 t/h

Diesel consumption: 14 l/h

Crushing jaws: MNMO

ASPHALT SLABS

auf 0/90

Product performance: 160 t/h

Diesel consumption: 15 l/h

Crushing jaws: MNMO

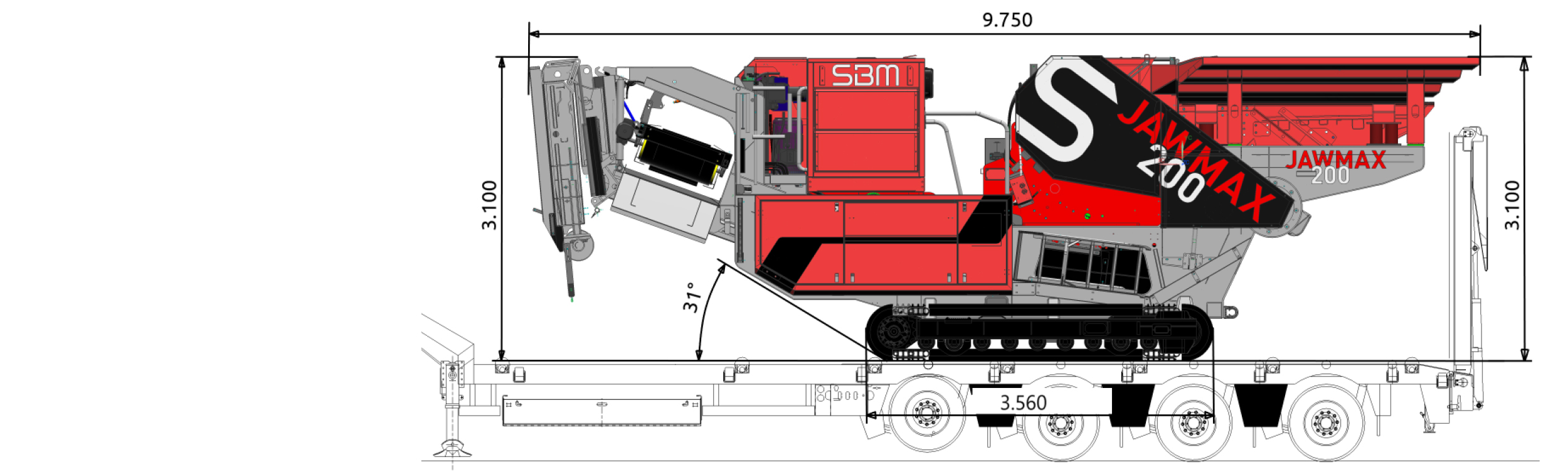

| TRANSPORT DIMENSIONS | Length | Width | Height | Weight |

|---|---|---|---|---|

| In transport | 9.750 mm | 2.550 mm | 3.100 mm | 27.500 kg |

| With 1-deck post-screening unit | 11.850 mm | 3.700 mm | 3.100 mm | 27.500 kg |

| TECHNICAL DATA | |

|---|---|

| Feed capacity (t/h) | up to 250 |

| Inlet crusher (W x H in mm) | 1.000 x 600 |

| Crusher drive (kW) | 75 |

| Diesel generator unit (kVA) | 150 |

| HARD FACTS | |

|---|---|

| Inlet opening | 1.000 x 600 mm |

| Feed size (max. diagonal space) | 0 - 550 mm (up to 400 kg per piece) |

| Feed capacity | max. 250 t/h |

| Final grain size | 0 - 60 to 0 - 220 mm |

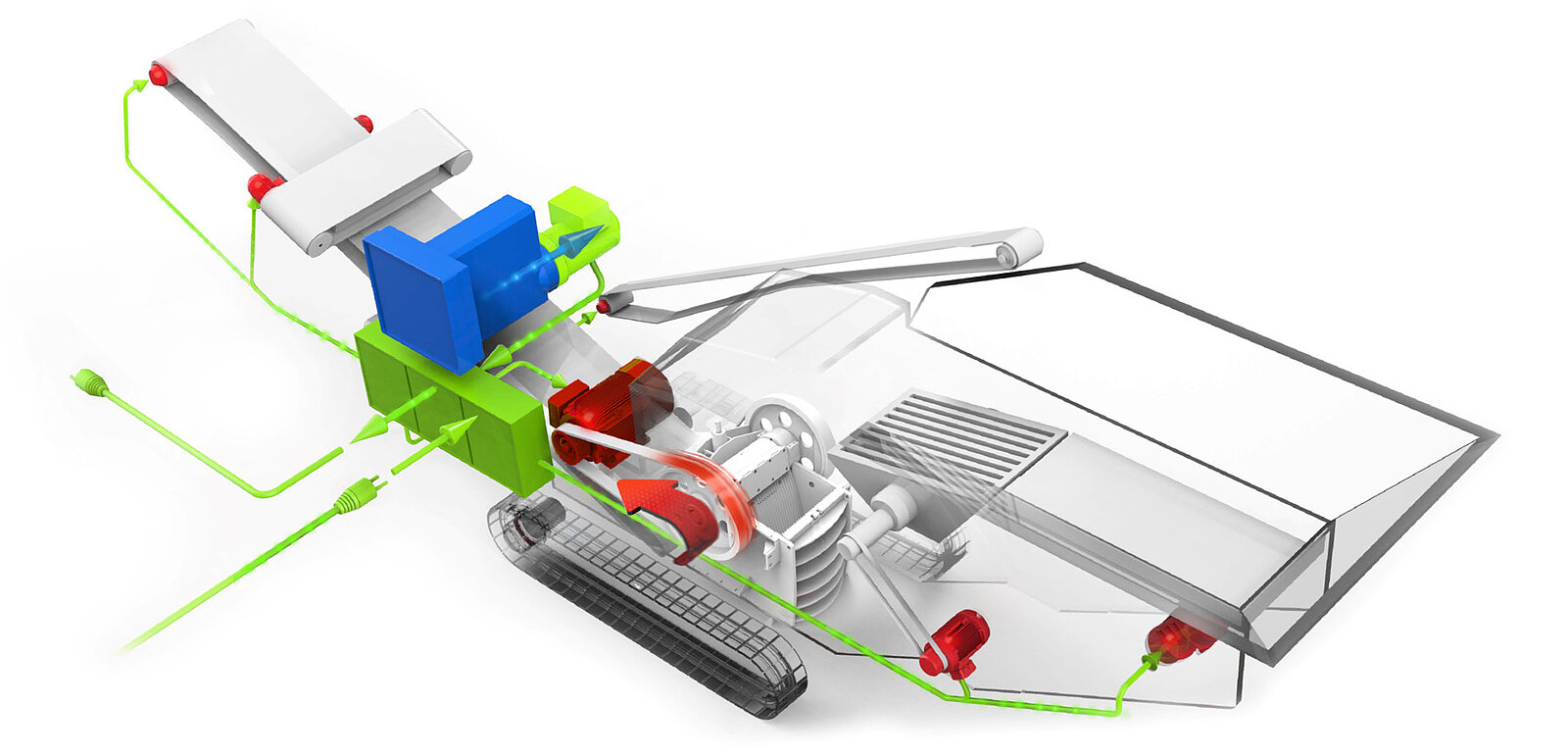

| DRIVE SYSTEM | |

|---|---|

| Motor | CUMMINS B6.7 |

| Operating speed | 2-stage |

| Tank capacity diesel/Adblue | 300l/38l |

| Generator | 150 kVA |

| Electric motor crusher | 75 kW (up to 112 kW peak) |

| Plug-in grid connection (option) | 400V, 150 kVA |

| Plug-out power supply | 400 V, 16A |

HYBRID PIONEERS – SINCE 1980

Only SBM consistently focusses on the advantages of purely electric drives for conveying, crushing and screening components in mobile crushing plants of all power classes. In autonomous diesel operation, a motor/generator unit supplies the energy at low, constant speeds: low-emission, quiet and extremely economical. All electric drives with their cable and plug-in connections are practically maintenance-free, cause no thermal or standby losses and significantly reduce environmental hazards caused by large volumes of hydraulic oil. In the optional mains operation, you simply flip a switch and everything on the system works as usual - only without diesel.

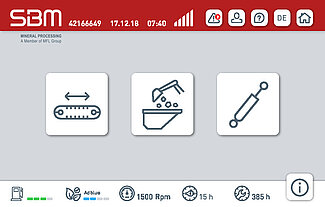

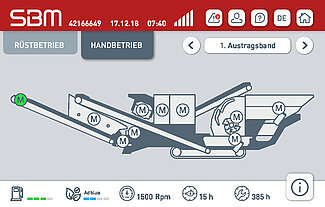

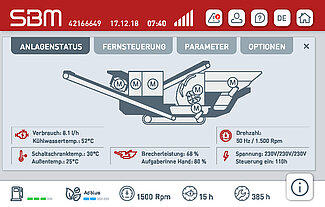

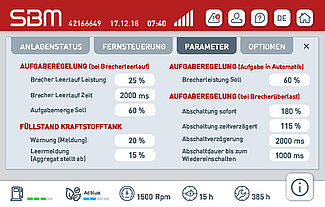

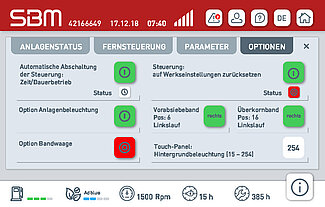

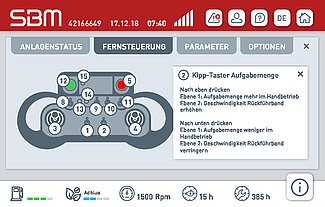

Everything under control with CRUSH CONTROL

Intuitive operation, fast reactions when necessary, and significant support for machine operators, technicians or dispatchers are the advantages of our CRUSH CONTROL control system with the mobile radio-based app solution.

INTUITIVE AND SAFE

- Simple plant start/stop via classic pressure keys

- Operator guidance and status display via 10-inch colour display

- Quick adjustment of performance parameters by touch screen

OPTIMISED PRODUCTIVITY

- Continuous monitoring of all plant functions

- Load-dependent crusher feeding via frequency-controlled feed chute

- Convenient and safe one-man operation of the complete plant via multifunctional remote control from the excavator/loader

KEEP ALWAYS INFORMED

- Real-time location and machine data via personalised app solution

- Data accessible anytime and anywhere via the internet

- Individually configurable information on operational data, production output (optional) and maintenance status of your plant

PROMPT AND EASY SUPPORT

- Authorised remote access to machine functions by SBM technicians or after-sales service

- Fast troubleshooting or process optimisation without on-site action possible